- Browse Categories

- VERTICAL FORM FILL SEAL MACHINE

- FILLING MACHINE

- CAPPING MACHINE

- LABELING MACHINE

- DOYPACK MACHINE

- MULTI LANE PACKING MACHINE

- FLOW WRAPPING MACHINE

- COFFEE/TEA PACKING MACHINE

- SHISHA PACKING MACHINE

- SNUFF PACKING MACHINE

- CARTONING MACHINE

- HARDWARE PACKING MACHINE

- CELLOPHANE PACKAGING MACHINE

- AUTO FEEDING PACKING LINE

- BLISTER PACKING MACHINE

- SEALING MACHINE

- STRAPPING MACHINE

- SHRINK WRAPPING MACHINE

- OTHER MACHINES

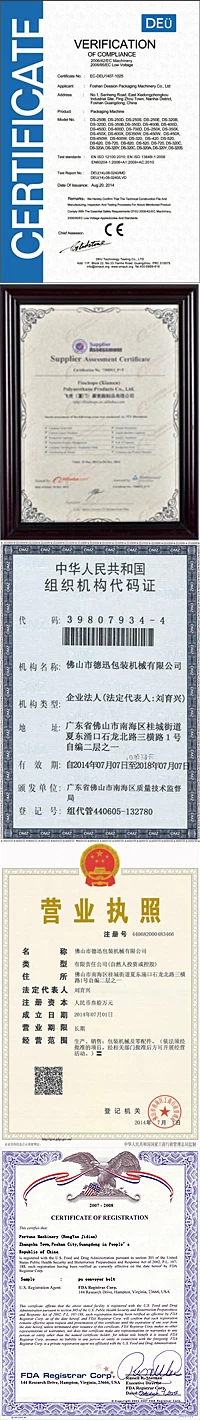

- Certifications

-

- Subscribe

-

Get email updates on new products

- Most new products

- Contact Us

-

FOSHAN DESSION PACKAGING MACHINERY CO., LTD

OFFICE NUMBER:0086 757 86087606

FAX:0086 757 86087051

ADDRESS:No.1 Sanheng Road, Shilong North Road, Pingzhou Town, Nanhai District, Foshan, Guangdong, China Contact Now

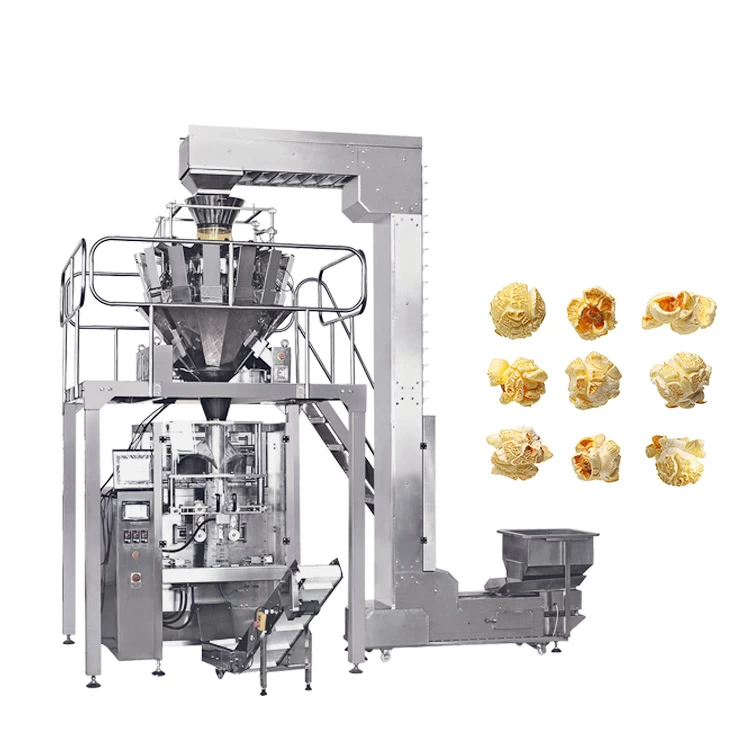

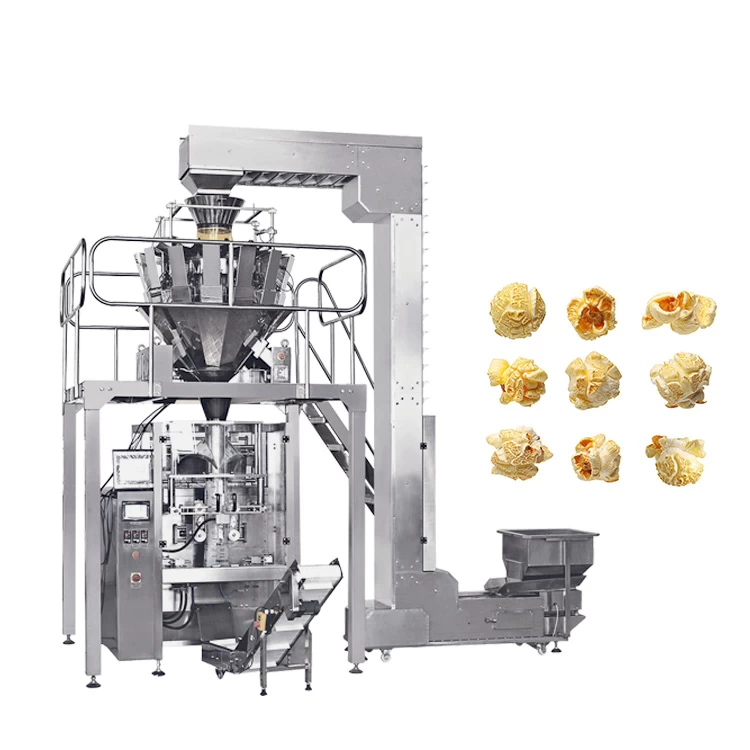

Automatic Industrial Snacks Packing Machine For Packaging Popcorn With Single Bucket Elevator

- Model: DS-420AZ

- Measurement Range: 150-1500ml

- Roll Width: Max.420mm

- Packing Speed: 5~60bags/min

- Bag Size: Length:80~300mm Width:60~200mm

- Film Roll Diameter: Max.320mm

- Film Thickness: 0.04-0.08mm

- Power: 220V,50HZ,2.2KVA

Automatic frozen dumpling packing machine with multi head weighing

Product Introduction:

All in one packing machine will weigh,pack,seal and hot-stamp the date code.Saves production floor space and labor cost.The combination is a good design in food packing,customers weigh and pack different products like rice,snack,chips,beans etc.

This machine cost is lowder than a full packing system for plants that need to get up and running quickly at a lower budget.

Machine Specifications:

| Machine Frame | Fully Stainless Steel #304 or carbon steel body |

| Touch Screen | 10inch touch screen to operate both weighing and bagger machine,multi langage display. |

| Weight Head | 10 |

| Hopper Capacity | 1.6L |

| Packing Speed | max.50bags per minute |

| Weighing Accurancy | +-0.1-1g |

| Max.Film Width | 420mm,laminated film |

| Control System | MCU control system on weigher and PLC on bagger |

| Bag Size | Length 60-230mm,Width 60-180mm |

| Power | 220V,50/60Hz2.22kw |

Machine Details:

Machine Combined parts:

1.Bag Making Machine

with Super touching screen to adjust parameters of plastic bags

2.Multi-head combination weigher (material weighing)

2/4 linear weigher,10/14/16 heads weigher,different materials suggest different weigher.

3.Material Conveyor

Z type elevator/Single bucket elevator/Large Inclined elevator

4.Optional component

Supporting Platform/Conveyor of Finished Product/Bag Former

1.Bag Making Machine

with Super touching screen to adjust parameters of plastic bags

2.Multi-head combination weigher (material weighing)

2/4 linear weigher,10/14/16 heads weigher,different materials suggest different weigher.

3.Material Conveyor

Z type elevator/Single bucket elevator/Large Inclined elevator

4.Optional component

Supporting Platform/Conveyor of Finished Product/Bag Former

Bag Sample

Machine Functions

1.New design and advanced techonology with beatiful appereace and reasonable structure .

2.Imported PLC system of computer control and colored touching screen enable easy operation.

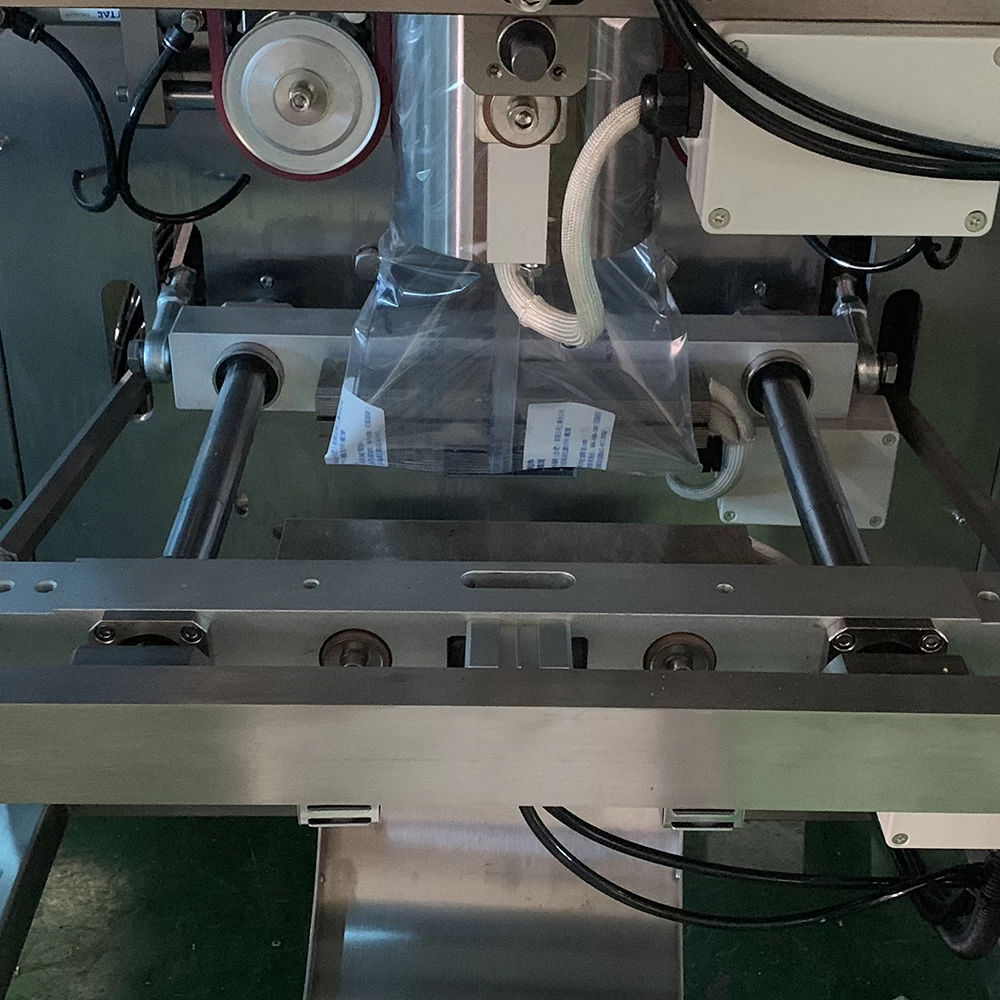

3.Imported film conveying system and color mark sensor achieve accurate position and beautiful package.External film placing makes the film installation easier and quicker.

4.Bags diversification provides customers with pillow bags, angle bags, hanging bags, linking bag, etc.

5.All the processes including conveying material, weighing, filling, bagging, date printing and finished good conveying are achieved automatically.

6.Packaging speed and length of bags can be set to some extent without further adjustment and parts changing.

7.Automatic correct function, saving time and packaging material.

2.Imported PLC system of computer control and colored touching screen enable easy operation.

3.Imported film conveying system and color mark sensor achieve accurate position and beautiful package.External film placing makes the film installation easier and quicker.

4.Bags diversification provides customers with pillow bags, angle bags, hanging bags, linking bag, etc.

5.All the processes including conveying material, weighing, filling, bagging, date printing and finished good conveying are achieved automatically.

6.Packaging speed and length of bags can be set to some extent without further adjustment and parts changing.

7.Automatic correct function, saving time and packaging material.

Machine Main Parts

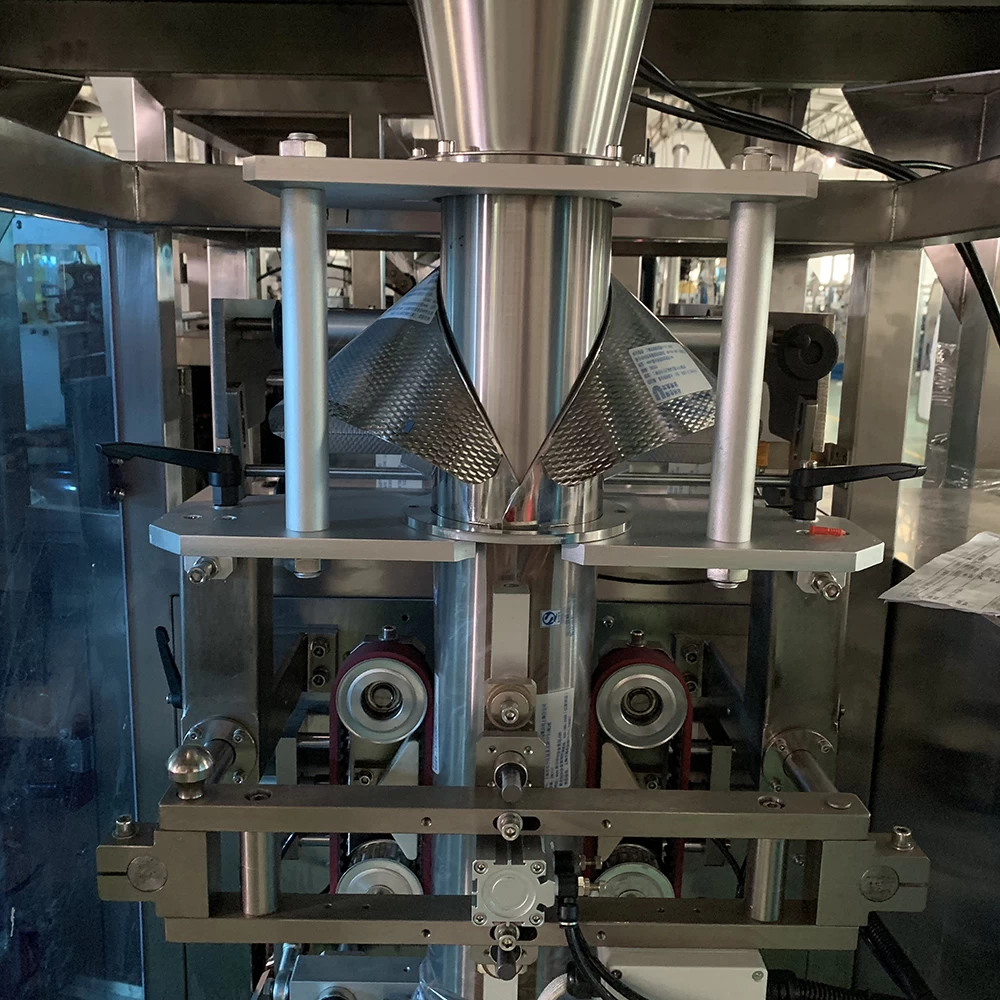

Name: Multi Heads Weigher

It is suitable for weighing of granule, slice, roll or irregular shape materials such as candy, seed, jelly, fries, coffee granule, peanut, puffy food, biscuit, chocolate, nut, yogurt pet food, frozen foods, etc. It is also suitable for weighing small hardware and plastic component

Machine Main Parts

Name: Vertical packing machine

Digital screen display with numerical setting and flexible operation;Imported PLC control system and color touching screen, easy operation;PID independent control of temperature, more suitable for different packaging material

Digital screen display with numerical setting and flexible operation;Imported PLC control system and color touching screen, easy operation;PID independent control of temperature, more suitable for different packaging material

Machine Optional Parts

Name: Z Type Elevator

Available for lifting of frangible and non-frangible material such as fried chips, prawn cracker, crispy rice, metals and medicines, etc.

Available for lifting of frangible and non-frangible material such as fried chips, prawn cracker, crispy rice, metals and medicines, etc.

Machine Optional Parts

Name: Supporting Platform

Adopting imported miniature motor and featured with low noise and long tifetime. It can transport finished goods to platform, reduce waste during packing, making the machine work more smoothly.

Adopting imported miniature motor and featured with low noise and long tifetime. It can transport finished goods to platform, reduce waste during packing, making the machine work more smoothly.

|

Package And Shipping

Automatic frozen dumpling packing machine with multi head weighing

Tag:

Foshan Dession Packaging Machinery Co., Ltd.

Tel:+86 13360354078

Wechat:+86 13360354078

Contact Person:Jenny Wu

PDF Show:PDF