- Browse Categories

- VERTICAL FORM FILL SEAL MACHINE

- FILLING MACHINE

- CAPPING MACHINE

- LABELING MACHINE

- DOYPACK MACHINE

- MULTI LANE PACKING MACHINE

- FLOW WRAPPING MACHINE

- COFFEE/TEA PACKING MACHINE

- SHISHA PACKING MACHINE

- SNUFF PACKING MACHINE

- CARTONING MACHINE

- HARDWARE PACKING MACHINE

- CELLOPHANE PACKAGING MACHINE

- AUTO FEEDING PACKING LINE

- BLISTER PACKING MACHINE

- SEALING MACHINE

- STRAPPING MACHINE

- SHRINK WRAPPING MACHINE

- OTHER MACHINES

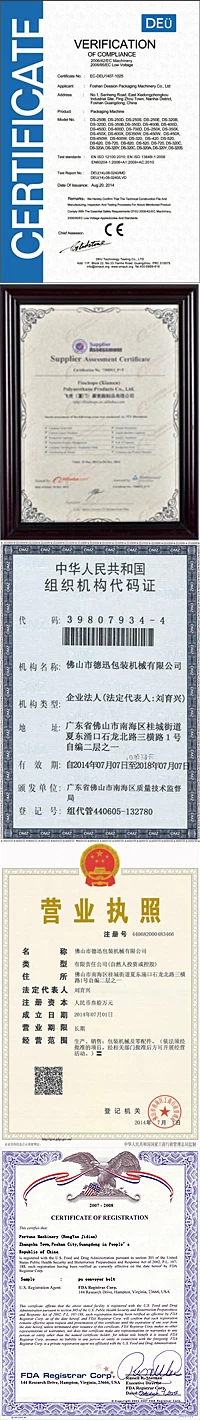

- Certifications

-

- Subscribe

-

Get email updates on new products

- Most new products

- Contact Us

-

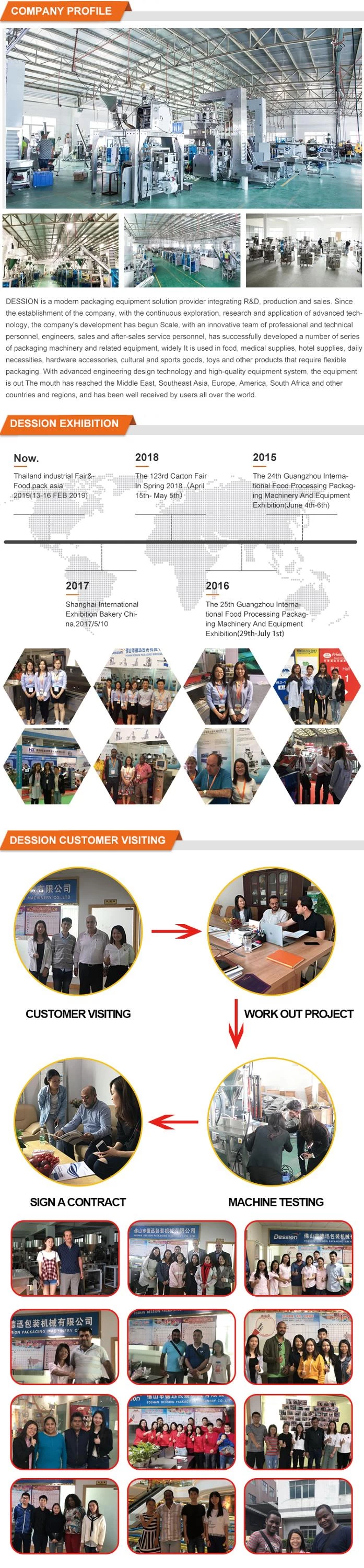

FOSHAN DESSION PACKAGING MACHINERY CO., LTD

OFFICE NUMBER:0086 757 86087606

FAX:0086 757 86087051

ADDRESS:No.1 Sanheng Road, Shilong North Road, Pingzhou Town, Nanhai District, Foshan, Guangdong, China Contact Now

Automatic honey chocolate fruit jam bag packing machine for decorating bread cake

- Model: DS-420LY

- Cutting method: liquid pump

- Bag type: back pillow case

- Measuring range: 100-1000g

- Bag size: 80-300mm (length), 50-200mm (width)

- Packaging speed 10-25 bags/min (speed, bag size and package weight)

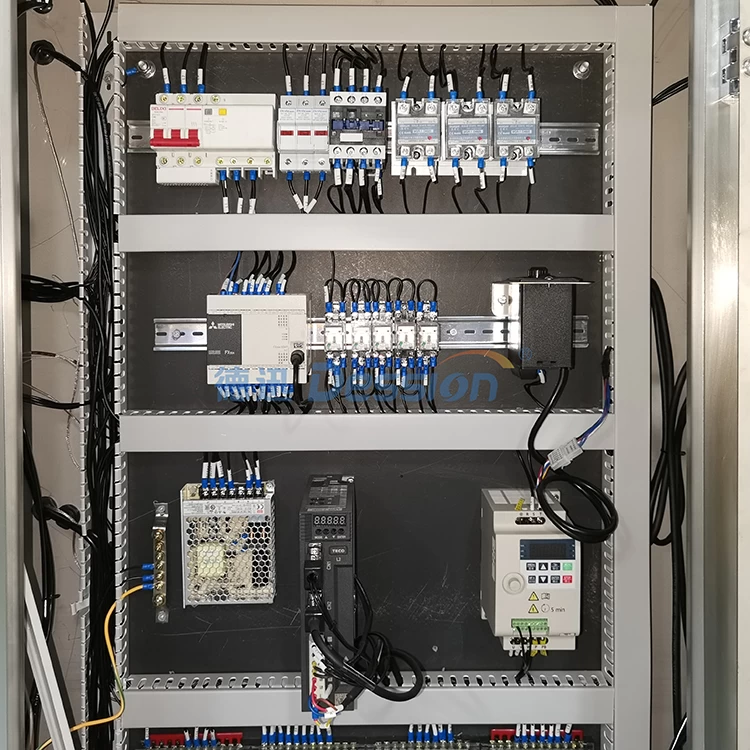

- Control mode: Chinese and English touch screen PLC control system

- Gas source: 0.3cbm/min, 0.65-0.8Mpa

- Power: 4.5 kW

- Power supply: 380V 50HZ

- Stainless steel body appearance

- Gross weight: 1200 kg

- Size: 1600 Width 2050 Height 2300 mm

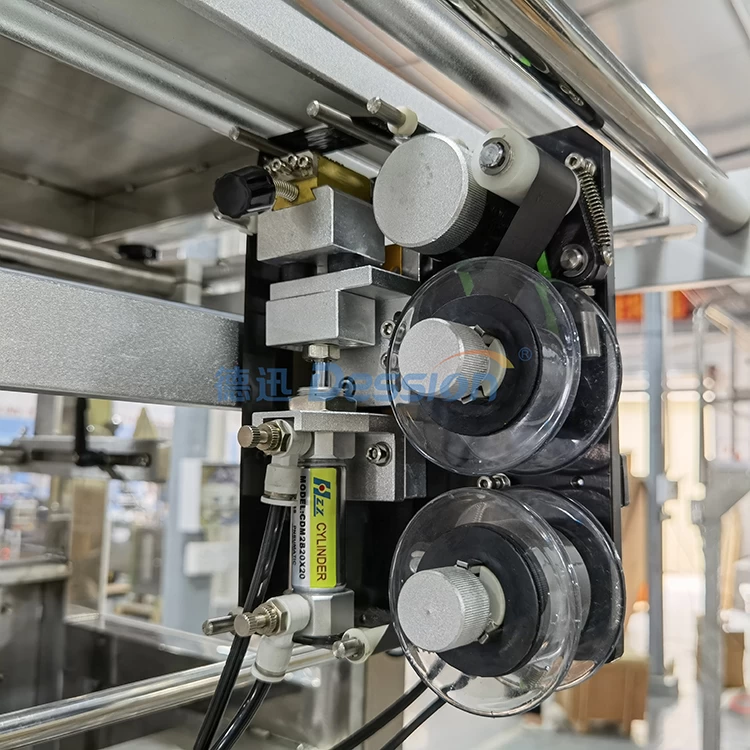

pump and hopper

pump and hopper Sealing part and bag maker

Sealing part and bag maker film holder

film holder cut part

cut part a sample

a sampleFirst: the general's job: The liquid filling machine uses PLC plus advanced photoelectric control system, Chinese and English touch screen. It can complete the processes of measuring, bag making, filling, sealing, cutting, production date printing, and cutting and tearing. It is measured by the principle of piston pneumatic ball valve pump and the measurement is accurate. The weight is set in the touch screen for ease of operation. The machine can be used for automatic packaging of various liquid paste materials in food, chemical, daily chemical and other industries, such as: shampoo, cooking oil, face cream, cream, jam, butter and so on.

Secondly, the equipment features

1. Chinese and English touch screen, intuitive and simple operation.

2, PLC computer control system, the operation is more stable, and any parameters can be set without stopping.

3. It can store ten groups of parameters and replace items more accurately.

4. The servo motor is used for traction and the positioning is more accurate.

5, independent temperature control system, precision can reach ±1 °C.

6, independent control of horizontal and vertical sealing temperature, can be well applied to a variety of composite films, PE film and other packaging materials.

7, the packaging style is diversified, back sealing, gusset, even bags, perforation and so on.

8, bag production, sealing, packaging, date printing completed in one go.

9. The working environment is clean and the noise is small.

okay ne photo

Shipping:

Upon receipt of payment, the delivery date will be in 15-30 working days,

By air, sea or express (DHL etc.)

Tel:+86 13360354078

Wechat:+86 13360354078

Contact Person:Jenny Wu

PDF Show:PDF