- Browse Categories

- VERTICAL FORM FILL SEAL MACHINE

- FILLING MACHINE

- CAPPING MACHINE

- LABELING MACHINE

- DOYPACK MACHINE

- MULTI LANE PACKING MACHINE

- FLOW WRAPPING MACHINE

- COFFEE/TEA PACKING MACHINE

- SHISHA PACKING MACHINE

- SNUFF PACKING MACHINE

- CARTONING MACHINE

- HARDWARE PACKING MACHINE

- CELLOPHANE PACKAGING MACHINE

- AUTO FEEDING PACKING LINE

- BLISTER PACKING MACHINE

- SEALING MACHINE

- STRAPPING MACHINE

- SHRINK WRAPPING MACHINE

- OTHER MACHINES

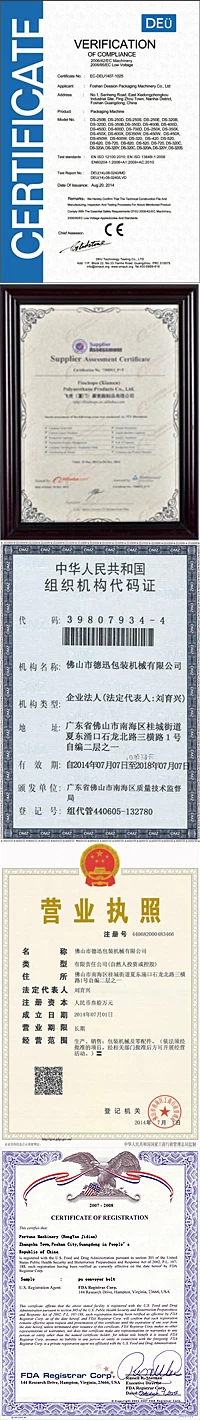

- Certifications

-

- Subscribe

-

Get email updates on new products

- Contact Us

-

FOSHAN DESSION PACKAGING MACHINERY CO., LTD

OFFICE NUMBER:0086 757 86087606

FAX:0086 757 86087051

ADDRESS:No.1 Sanheng Road, Shilong North Road, Pingzhou Town, Nanhai District, Foshan, Guangdong, China Contact Now

Automatic Shrink Sleeve Applicator With Steam Tunnel Heating Bottle Shrink Sleeve Labeling Machine

- Labeling speed: about 0-120P/min (depending on product and label size)

- Sleeve labeling accuracy: ±1mm (excluding errors in product labels, etc.)

- Applicable product size: diameter φ25mm~φ110mm, height 30mm~280mm

- Applicable label range: length 20~260mm

- Maximum label supply: outer diameter within 500, inner diameter 76mm

- Ambient temperature/humidity: 0-50℃/15-85%

- Voltage specification: AC220/380V, 50HZ

- Dimensions and weight: about 5000 long, 1050 wide, 2000 high, 2000mm/about 300Kg

Automatic Shrink Sleeve Applicator With Steam Tunnel Heating Bottle Shrink Sleeve Labeling Machine

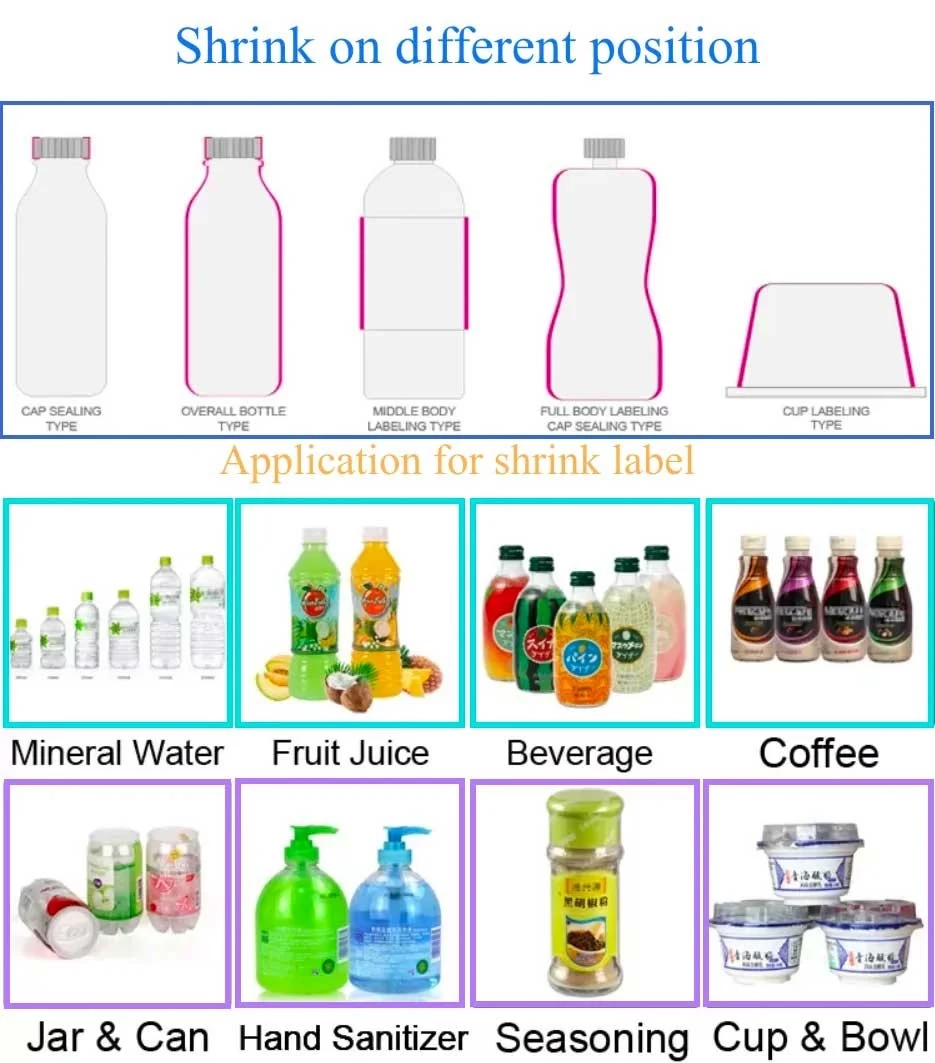

Automatic sleeve label shrinking machine, the series of equipment consists of bottle entering, bottle separating, sleeve label, and shrinking functions in one of the fully automatic intelligent packaging line, High-speed, accurate positioning, manpower streamlining, and perfect packaging is the spirit of this equipment design, suitable for beverage and health food factory, with beautiful, easy to clean and maintenance functions

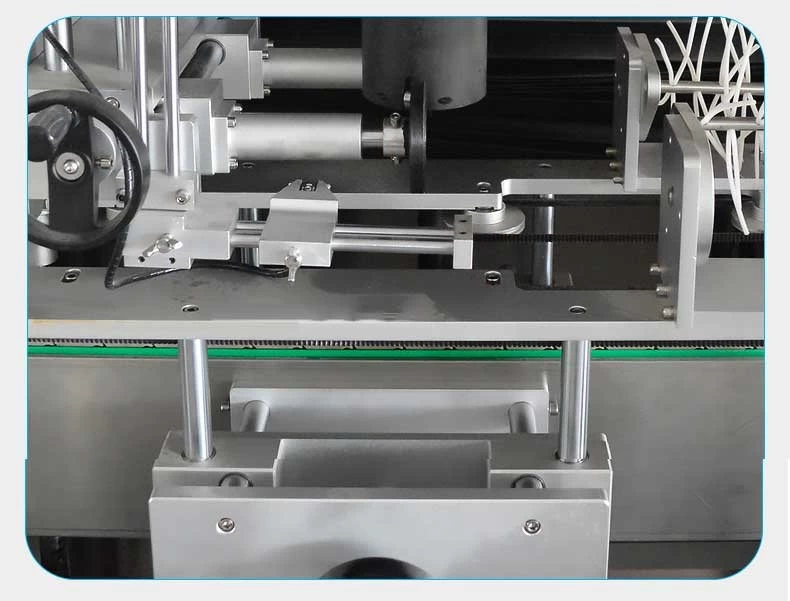

In the new steam shrinkage furnace, the heat shrinkage efficiency is greatly improved, for different and irregular round bottles, square bottles, flat bottles, and other bottle shapes, adjustment, maintenance convenience, shrinkage leveling, the whole machine using waterproof design, stainless steel composition, easy operation, and maintenance.

This fully automatic sleeve labeling machine is suitable for various kinds of bottles, like round bottles, square bottles, oval bottles, etc. This machine can automatically feed and cut film, and it can sleeve labels precisely, greatly saving labor and improving work efficiency. Widely used for beverage bottles, cosmetic bottles, shampoo bottles, etc.

1. The new bottle label steam shrinking furnace has greatly improved heat shrinkage efficiency and is suitable for various plastics and glass bottles. For different bottle types and irregular round bottles, square bottles, flat bottles, etc., the furnace is easy to adjust and maintain. Shrinkage is flat.

2. The steam injection method adopts the design of a steam distribution package, and adjustable steam guiding system, the pipeline is smooth and does not occupy space, and the discharge outlet is divided into three sections on each side. The height of each section, front, and rear, and air volume can be adjusted separately to reach the maximum. Good shrinkage effect.

3. The low-pressure steam distribution bag is designed with seamless steel pipe, and each connecting pipe uses a stainless steel hose quick connector, which is convenient for disassembly and installation.

4. The whole machine casing is made of stainless steel SUS304, which saves energy and meets food safety standards.

5. The bottom stainless steel water tray is concentrated with condensed water, which can be taken out, and the working environment is not affected.

With a professional after-sales service team, we can provide you with satisfactory and technical service no matter which country you are in;

Any videos of packing machine installation, adjusting, setting, and maintenance are available for any buyer;

If you have any problem when using the machine and the videos can not help, our technician will video chat with you to fix your problem;

(Notice: In order to save your cost, we offer various video chatting services for you, but if you insist on the service overseas, the travel expense and technician cost will paid by you.)

Upon receipt of payment , delivery date will be in 15-30 working days, By Air, by Sea or by Express (DHL etc)

FAQ

Q1. Are you a manufacturer?

A1: Yes, we are an experienced manufacturer with our own brand and production lines, welcome to visit our factory at your convenient time.

Q2. How about the quality of products?

A2: Our technicians and QC teams test the products one by one using aging lines, professional devices, and instruments to ensure the quality of all products.

Q3. How about the price?

A3: We are a manufacturer and always offer our customers the most competitive prices.

Q4. How to place an order?

A4: Contact with online service, or send an email to us directly, we will reply to you with the product price, specifications, packing, etc. soon. Thank you.

Q5. May I send samples to you for testing?

A5: Yes! You are welcome to send us your products to test by our machine.

Q6. How long is your delivery time?

A6: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock.

Tel:+86 13360354078

Wechat:+86 13360354078

Contact Person:Jenny Wu

PDF Show:PDF